Inspection entity

Focus on waste water management: quality assurance through regular inspections

As a state-approved testing centre for flow measurement devices and throttles, we help to ensure that water management systems meet the highest standards. Since 1997, we have inspected over 2,500 flow mass meters and around 6,500 throttles – using state-of-the-art measurement technology and minimising the effort required by operators.

We offer the following services as part of our testing centre activities:

- Throttle inspections in accordance with the significant national regulations SüwVO Abw , EKVO

- Inspection of flow measuring points in accordance with the significant national regulations SüwV-kom , EKVO

You can find our current certificates under Service & Downloads.

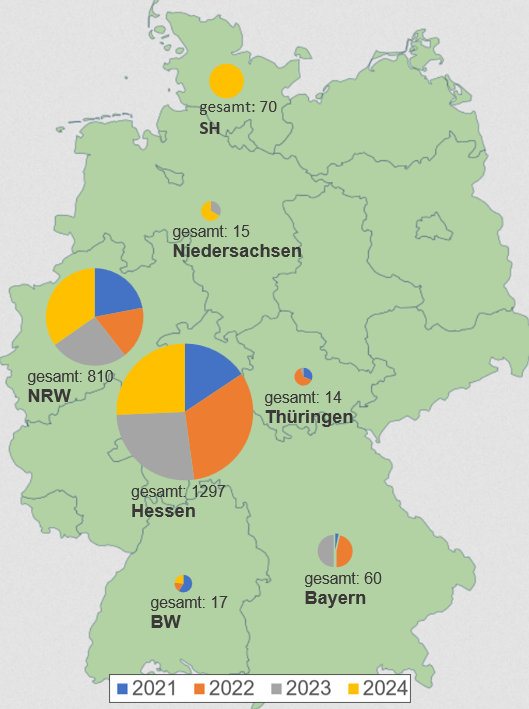

We inspect devices in large parts of Germany. However, due to the different legal regulations of the federal states, we concentrate our activities particularly in Hesse and North Rhine-Westphalia, as shown in Figure 1.

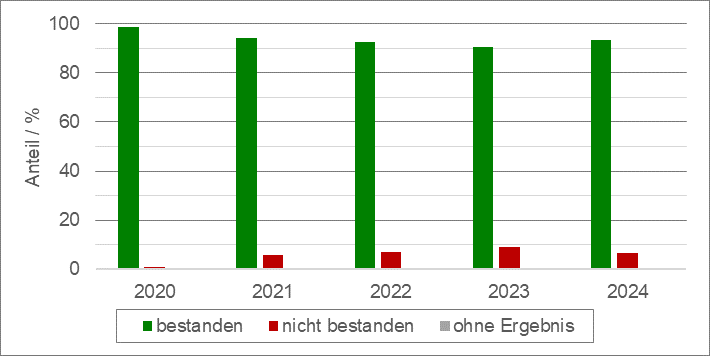

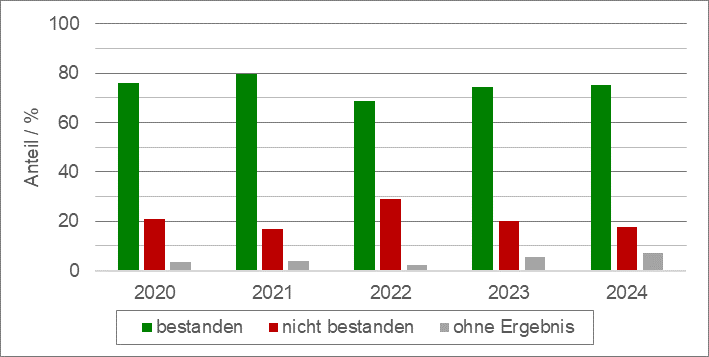

Figures two and three substantiate the results of the inspections in the years 2020 to 2024. In the period from 2020 to 2024, over 90% of the inspected flow mass meters passed. The proportion of throttling devices that did not pass rose to approx. 29% in 2022. This is due to an increased number of initial inspections of throttle systems. From 2022 onwards, the proportion of throttles that failed the testing fell continuously from 29% to 18% in 2024.

These figures demonstrate the increasing quality and reliability of the installations. They also emphasise the importance of regular inspections to ensure high standards in water management.

Figure 1: Number of throttle inspections by federal state in the years 2021 to 202

Inspection of flow measurement points according to SüwV-kom and EKVO

Motivation

Flow measurement devices in sewage plants serve, among other things, the purpose of assessing and calculation sewage charges. Our experience shows that measurement results are often too high and thus unjustly lead to excessive sewage charges – often without the operator of the plant being aware of it.

Demands of the Regulations

The federal self-monitoring ordinances for operators of such plants lead to an obligation for verification.

Figure 2: Results of the flow measurement inspections in the years 2020 to 2024

Planning

- Inspection of technical documents of the flow measurement devices as well as construction

- and site plans

- Establishing an exact schedule for the measurement campaign (Of course, in coordination with you!)

Execution

- Visual assessment of the flow measurement devices

- Installation of the reference instruments of measurement

- Reference measurement under conditions of operation

Project completion

- Inspection report

Inspection of flow control or metering valves according to SüwVO Abw and EKVO

Motivation

Flow control and metering valves restrict the effluent flow into the following channel or sewer network. False tuning or settings result in an imbalance of the system of sewage network/rainwater basin and outlet channels/sewage plant.

This imbalance can cause extensive consequences:

- Lower deviation of the water supposed to go through the throttle

– Increased input of dirt load into the water due to increased discharge

– More frequently exhaustion of the basin level

- Exceedance of the water supposed to go through the throttle

– The capacity of the basis is not exploited.

– Hydraulic overload of the following channel/ sewer network and the sewage plant.

– Violation of the discharge rates noted in the permit notification.

Demands of the Regulations

There has to be an inspection of the flow control and metering valves every 5 years according to SüwVO Abw and EKVO.

Figure 3: Results of the throttle inspections in the years 2020 to 2024

Planning

- Inspection of technical documents of the flow measurement devices as well as construction and site plans

- Establishing an exact schedule for the measurement campaign (Of course, in coordination with you!)

Execution

- Visual assessment of the flow measurement devices

- Installation of the reference instruments of measurement

- Reference measurement under conditions of operation

Project Completion

- Inspection report